Video tutorials to make a 2D o 3D nice house planning

And more...

And the printable tutorial

Thursday, 10 December 2015

Thursday, 3 December 2015

Monday, 30 November 2015

Saturday, 21 November 2015

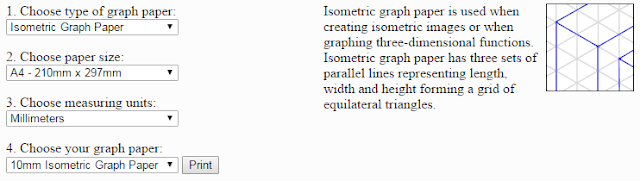

Isometric graph paper

In this site you can print isometric and other types of graph paper in differents sizes and spacings,

http://www.printfreegraphpaper.com/

http://www.printfreegraphpaper.com/

Sistema dièdric

Generació de vistes

En les següents pàgines trobareu exercicis de vistes de diversos nivells, alguns amb possibilitat de fer girar la figura per dibuixar-la millor.Nivell elemental - online

Nivell elemental - fitxa en pdf

Nivell mig - online

Nivell mig - fitxa en pdf

I aquí podeu generar els vostres propis exercicis:

http://www.educacionplastica.net/3dcube_model/3d_gen_eje.htm

Generació de peces a partir de vistes

I aquí trobareu exercicis ordenats per nivells per generar peces a partir de les vistes.

Les de nivell 0 són de diferents colors per ajudar a veure els diferents blocs.

Wednesday, 11 November 2015

Monday, 9 November 2015

Materials - Who is who?

Which material do I have in the bag?

- Make teams of 4 people.

- Each team writes a list of 4 to 8 different materials and make sure they know the properties of them and what they are used for.

- The teams take turns to make questions that can be answered by "yes", "no", "quite", "not really" in order to guess which material the other team has in its bag? Each time the question must be asked by a different member of the team.

Is it ... [material]?

List of properties

|

List of materials

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Friday, 6 November 2015

Thursday, 22 October 2015

Wednesday, 14 October 2015

WOOD BURNING WITH ELECTRICITY

What happens when you apply 15000 volts to a wood plank? Find out in this video.

IMPOSSIBLE NAIL-THROUGH-WOOD

How is this nail put into this piece of wood?

There is no other possibility but to twist the wood and reshaping it after putting the nail in place, but to do this you must alter the wood properties, because it can't be done if the wood is rigid.

You'll get the answer in this video:

There is no other possibility but to twist the wood and reshaping it after putting the nail in place, but to do this you must alter the wood properties, because it can't be done if the wood is rigid.

You'll get the answer in this video:

MATERIALS

Some interesting articles from the Explain That Stuff website:

MATERIALS SCIENCE

http://www.explainthatstuff.com/materials-science.html (14/10/2015)WOOD

http://www.explainthatstuff.com/wood.html (14/10/2015)METALS

http://www.explainthatstuff.com/introduction-to-metals.htmlPLASTICS

COMPOSITES AND LAMINATES

COMPONENTS, JOINTS AND ADHESIVES

Components are the smaller parts that make up a product, often used to join materials together. Different kinds of component are used to join plastics, woods and metals, and adhesives are used to join materials together by glueing.

Components

Components made from resistant materials are usually bought ready-made. The most common components are nails, screws, hinges andcatches.

Common components

| Component | Description and use |

|---|---|

| Nails | Generally used where appearance is not important or where a quick job is needed. Made of mild steel. |

| Panel pins and veneer pins | Used to fix backs onto cupboards and bottoms onto boxes. Veneer pins are finer (or thinner). Made of mild steel. |

| Wood screws | Used to join metal or plastic components to wood, or to join two pieces of wood to make a strong joint. |

| Machine screws | Have a screw thread to fit into a threaded hole or a hexagonal nut. They can be used to join two or more pieces of metal or plastic. |

| Bolts | Have a screw thread which fits into a threaded hole or a hexagonal nut, and are normally used to join two or more pieces of metal or plastic. A bolt is only threaded for part of its length. Bolts normally have hexagonal heads. |

| Set screws | Have a screw thread along the whole or most of their length, and normally have hexagonal heads. |

| Pop rivets | Originally designed for use in the aircraft industry but are now used in many different products. They are often used where there is only access to one side of the material. |

| Hinges, catches and locks | Used on boxes, cabinets and cupboards. They can be used on products made from wood, metal or plastic. They are normally fixed to the product with wood screws or machine screws and nuts. |

JOINING METAL

Metal joints can be made by brazing, soldering, welding or using rivets.

Brazing

Brazing is a way of bonding materials by melting a filler metal or alloy between the components. The filler metals used in brazing must have a lower melting point than that of the material being joined. Brazing forms very strong, permanent joints.

Soldering

Soldering is a type of brazing which works at lower temperatures.

- Soft soldering is used to make permanent joints between copper, brass, tin-plate or light steelwork, and is normally used to join components to electronic circuit boards.

- Hard soldering is used for stronger joints.

Welding

In welding, two pieces of metal are melted along the joints - fusing together as they cool. No filler is used. A filler rod may be used for a really strong joint.

Machine screws

Machine screws are special screws for joining metal components. Holes have to be pre-drilled into the component. They must have the correct internal thread.

Rivets

Rivets are used to join metal, plastics and plywood. The rivet is placed in a hole drilled through both pieces of material, and its end beaten into a dome. A tool called a rivet set or a rivet snap is used to to finish the joint. Some rivets are countersunk.

Pop rivets are used where there is only access to one side of the work. They are used to join thin sheets of material together.

JOINING WOOD

The method used for joining wood will depend on the function, strength and quality of the product.

Wood joints can be made with screws, nails, glues and knock-down components, or with frame joints, such as butt joints, halving joints, mortice-and-tenon, dovetail and box joints.

Screws

Two sizes of hole are needed. The clearance hole must be very slightly bigger than the shankof the screw so that the shank can move freely in the clearance hole. The pilot hole must be smaller than the core of the screw so that the core fits tightly into it.

Nails

Nails are cheaper and easier to use than screws and come in many shapes and sizes. Holes need to be drilled to prevent the wood from splitting, or when using hard woods.

Knock-down joints

Knock-down (KD) joints are commonly used in flat-pack furniture, which is assembled by the customer at home. Usually KD joints are made from a plastic, such as nylon.

Frame joints

Strong, permanent and neat-looking joints in wood are achieved using one of the many types of frame joint. Frame joints are right-angled, jointed frames common in furniture, boxes and many other types of assembly.

Simple frame joints

More complex frame joints

Edging

Lipping is a strip of wood used to reinforce a joint, or to make the edge of a piece of wood look neater.

With floorboards or timber cladding, the edge of a thin strip of wood fits into a slot in the next piece of wood. This is called a tongue-and-groove joint.

SMART MATERIALS

Smart materials

Smart materials are reactive materials. Their properties can be changed by exposure to stimuli, such as electric and magnetic fields, stress, moisture and temperature.

Smart colours

Smart colours are pigments which can be incorporated into paints, dyes, inks and plastics.

- thermochromic pigments react to changes in temperature

- photochromic pigments react to changes in light levels

Photochromatic materials are used in the manufacture of sunglasses. Exposure to sunlight causes the lens of the glasses to darken to protect the eye.

Polymorph

Polymorph is available in small pellets which fuse together when heated to 62˚C. It can be moulded into shape resulting in a very tough polymer. Unused pellets can be re-heated and re-used.

Polymorph is used for:

- manufacturing awkward shapes such as ergonomic handles

- joining components together

- making moulds for vacuum forming

Smart grease

Smart grease is used to control movement, producing a dampened, slowed down feeling. For example, smart grease is used on volume control knobs and microscope slides.

Conductive polymers

Most plastics are natural insulators. The advantages of making plastics which areconductors are:

- they are easier to manufacture

- they are lighter and cheaper than metals

- they prevent the build-up of static electricity which can damage microcircuits

Some conductive polymers are also biocompatible, making them suitable for use in medical devices.

Nanomaterials

Nanoparticles improve the mechanical properties of a material, such as stiffness orelasticity. When incorporated into polymers, they can be used as lightweight replacements for metals.

Nanomaterials are used in car manufacturing to create cars that are faster, safer and more fuel efficient. They can also be used to produce more efficient insulation and lighting systems.

PLASTICS

Plastics

Sources of plastics

Natural

Natural sources of plastics include:

- plants - from which cellulose can be extracted

- trees - from which latex, amber and resin can be extracted

- animals - from which horn and milk (used to make glues) are obtained

- insects - from which shellac (used to make polish) is obtained

Synthetic

Synthetic plastics are chemically manufactured from:

- crude oil

- coal

- natural gas

Thermoplastics and thermoset plastics

Plastics are divided into thermoplastics and thermoset plastics.

Thermoplastics can be heated and shaped many times.

Properties and uses of thermoplastics.

| Name | Properties | Principal uses |

|---|---|---|

| Polyamide (Nylon) | Creamy colour, tough, fairlyhard, resists wear, self-lubricating, good resistance to chemicals and machines | Bearings, gear wheels, casings for power tools, hinges for small cupboards, curtain rail fittings and clothing |

| Polymethyl methacrylate (Acrylic) | Stiff, hard but scratches easily, durable, brittle in small sections, good electrical insulator, machines and polishes well | Signs, covers of storage boxes, aircraft canopies and windows, covers for car lights, wash basins and baths |

| Polypropylene | Light, hard but scratches easily, tough, good resistance to chemicals, resists work fatigue | Medical equipment, laboratory equipment, containers with built-in hinges, 'plastic' seats, string, rope, kitchen equipment |

| Polystyrene | Light, hard, stiff, transparent, brittle, with good water resistance | Toys, especially model kits, packaging, 'plastic' boxes and containers |

| Low density polythene (LDPE) | Tough, good resistance to chemicals, flexible, fairly soft, good electrical insulator | Packaging, especially bottles, toys, packaging film and bags |

| High density polythene (HDPE) | Hard, stiff, able to be sterilised | Plastic bottles, tubing, household equipment |

Thermoset plastics can only be heated and shaped once.

Properties and uses of the thermoset plastics.

| Name | Properties | Principal uses |

|---|---|---|

| Epoxy resin | Good electrical insulator, hard, brittle unless reinforced, resists chemicals well | Casting and encapsulation, adhesives, bonding of other materials |

| Melamine formaldehyde | Stiff, hard, strong, resists some chemicals and stains | Laminates for work surfaces, electrical insulation, tableware |

| Polyester resin | Stiff, hard, brittle unless laminated, good electrical insulator, resists chemicals well | Casting and encapsulation, bonding of other materials |

| Urea formaldehyde | Stiff, hard, strong, brittle, good electrical insulator | Electrical fittings, handles and control knobs, adhesives |

METALS

Most metals are extracted from their ores using a chemical reaction. Metals are rarely used in their pure form, and are usually mixed with other metals to improve their properties. This is called an alloy. Most metals are good conductors and can be recycled.

Ferrous metals

Ferrous metals contain iron. Examples are cast iron, mild steel, medium carbon steel, high carbon steel, stainless steel and high speed steel.

The ferrous metals listed below are all alloys.

Composition, properties and uses of ferrous metals

| Name and melting point | Properties and characteristics | Principal uses |

|---|---|---|

| Cast iron 1200°C | Hard skin, softer underneath, but brittle,corrodes by rusting | Parts with complex shapes which can be made by casting |

| Mild steel 1600°C | Tough, ductile, malleable, good tensile strength, poor resistance to corrosion | General purpose engineering material |

| High carbon steel 1800°C | Even harder than medium carbon steel and more brittle, can be heat-treated to make it harder and tougher | Cutting tools, ball bearings |

| Stainless steel 1400°C | Hard and tough, resistant to wear and corrosion | Cutlery, kitchen equipment |

Non-ferrous metals

Non-ferrous metals do not contain iron. Some common non-ferrous metals are aluminium, Duralumin, copper, zinc, brass, gilding metal and tin.

Composition, properties and uses of non-ferrous metals:

| Name and melting point | Composition | Properties and characteristics | Principal uses |

|---|---|---|---|

| Aluminium 660°C | Pure aluminium | Good strength-to-weight ratio, light, soft, ductile, good conductor of heat and electricity | Kitchen equipment, window frames, general cast components |

| Copper 1080°C | Pure copper | Malleable and ductile, good conductor of heat and electricity, resistant to corrosion | Water pipes, electrical wire, decorative goods |

| Brass 900-1000°C | Alloy | Resistant to corrosion, fairly hard, good conductor of heat and electricity | Ornaments, cast items such as water taps |

| Tin 230°C | Pure tin | Soft, weak, malleable, ductile and resistant to corrosion | Usually used for coating steel to form tin-plate, soft solder |